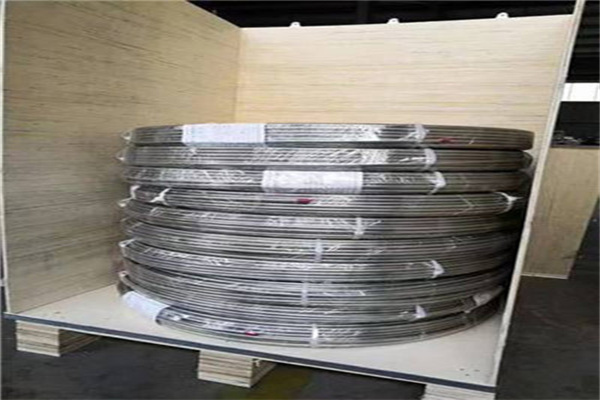

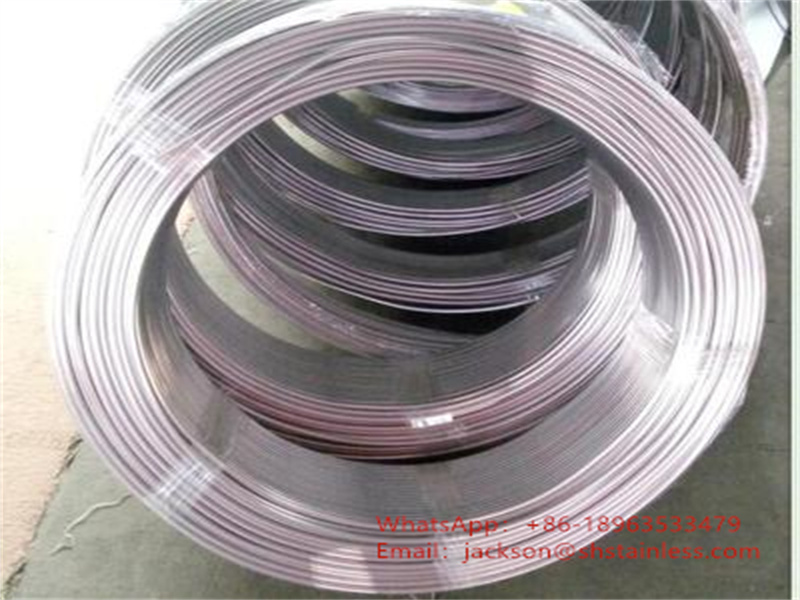

ASTM A213, A269 904L zitsulo zosapanga dzimbiri zokutira machubu ku China

Aloyi 904L ndi chosakhazikika, high alloy austenitic chitsulo chosapanga dzimbiri chokhala ndi mpweya wochepa.Amagwiritsidwa ntchito kwambiri m'mapulogalamu omwe zinthu zowonongeka za TP316/L ndi TP317/L sizokwanira.Alloy imaperekanso mawonekedwe abwino kwambiri, kuwotcherera, komanso kulimba.Kuphatikizika kwa mkuwa kumapereka aloyi 904L zosagwira dzimbiri zomwe zimakhala zapamwamba kuposa zitsulo zosapanga dzimbiri za nickel za chrome.Zitsanzo zimaphatikizapo kukana sulfuric, phosphoric, ndi acetic acid.

Size Range

| Diameter yakunja (OD) | Makulidwe a Khoma |

| .250”–1.000” | .035″–.065″ |

Kuzizira komalizidwa ndi kowala annealed chubu.

Zofunika Zamankhwala

Aloyi 904L (UNS N08904)

Zolemba %

| C Mpweya | Mn Manganese | P Phosphorous | S Sulfure | Si Silikoni | Cr Chromium | Ni Nickel | Mo Molybdenum | N Nayitrogeni | Cu Mkuwa |

| 0.020 max | 2.00 max | 0.040 kukula | 0.030 kukula | 1.00 max | 19.0–23.0 | 23.0–28.0 | 4.0–5.0 | 0.10 max | 1.00–2.00 |

Dimensional Tolerances

| OD | OD Kulekerera | Kulekerera Pakhoma |

| ≤.500″ | ± .005” | ± 15% |

| 0.500 "-1.500" | ± .005” | ± 10% |

Mechanical Properties

| Mphamvu Zokolola: | 31 nsi |

| Kulimba kwamakokedwe: | 71 nsi |

| Kutalikira (mphindi 2″): | 35% |

| Kulimba (Rockwell B Scale): | 90 HRB Max |

Kupanga

Aloyi 904L si maginito mu zinthu zonse ndipo ali formability kwambiri ndi weldability.Mapangidwe a austenitic amapatsanso kalasiyi kulimba kwambiri, ngakhale mpaka kutentha kwa cryogenic.

Ntchito Zamakampani

Chemical process

Kuchuluka kwake kwa chromium ndi faifi tambala, pamodzi ndi kuwonjezera kwa molybdenum ndi mkuwa, alloy 904L amathandizira kuyimirira ku sulfuric, phosphoric ndi acetic acid.Izi ndizothandiza makamaka popanga ma asidi ndi feteleza.

Lembani uthenga wanu apa ndikutumiza kwa ife